By Yashar Mousavand

What this page is and is not

Normalization and thermal cycling are often described as a ritual step that magically improves forged blades. In reality they are conditioning treatments that change grain size, carbide distribution, residual stress, and hardening response, but only within the limits set by alloy chemistry and prior damage. This article breaks down the mechanisms and then maps them to real blade problems so you can choose the right post forging path and avoid cycles that waste time or make outcomes less repeatable.

Key takeaways

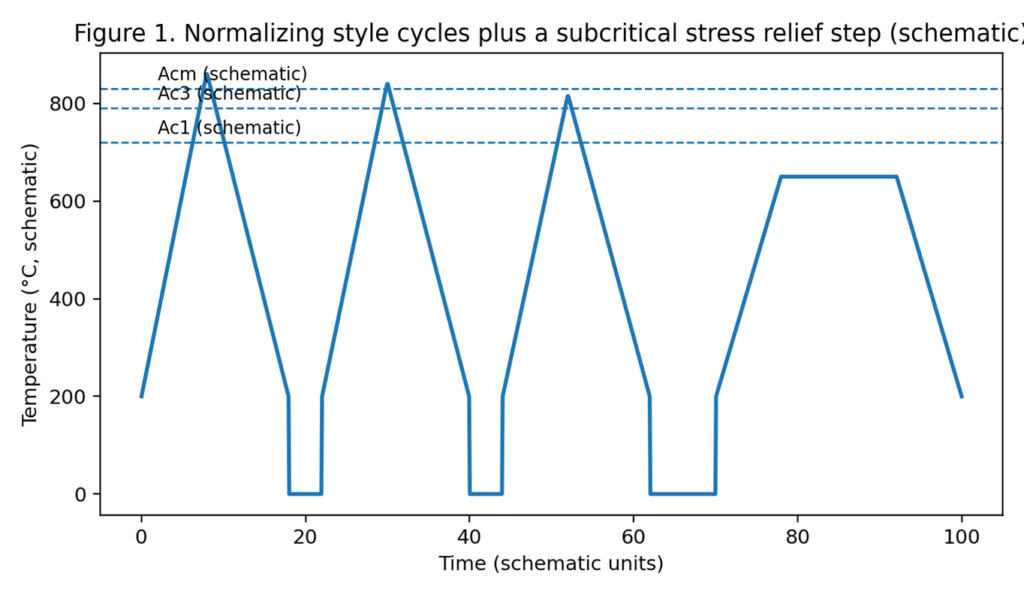

- Normalizing is defined industrially as heating a steel above the transformation range to fully austenitize and then cooling in air to below transformation. In practice, the target is typically above the upper critical temperature Ac3 (hypoeutectoid) or Acm (hypereutectoid).

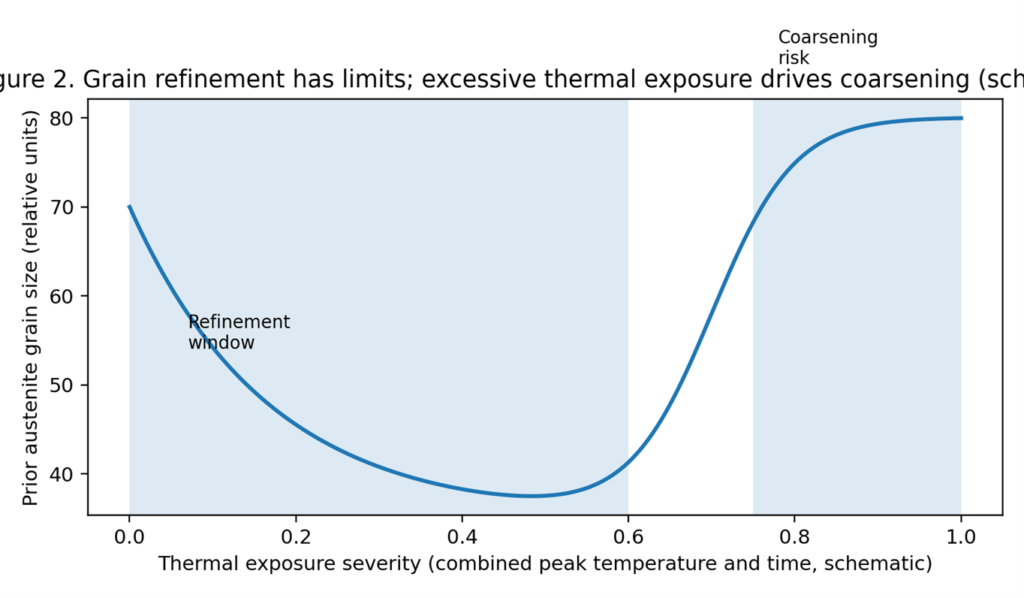

- Thermal cycling in knifemaking usually means multiple heat and cool cycles after forging and before final austenitize and quench. It can refine grain and improve hardening response, but it can also increase grain size if the peak temperature or time is too high.

- Normalization and cycling can reduce forging induced stress and increase microstructural uniformity, but they cannot undo decarb, cracks, or true overheating damage sometimes called ‘burning’.

- Cooling conditions matter as much as peak temperature. Air cooling is not one cooling rate. Mass, section size, and how parts are stacked can shift the result toward fine pearlite, coarse pearlite, bainite, or even martensite in hardenable alloys.

- The most useful way to think about post forging cycles is as a controlled reset for the starting condition of final heat treatment. If you cannot describe the starting condition you want, you cannot choose the right cycle.

1. Definitions that matter in blades

1.1 Normalizing

Normalizing is the conditioning heat treatment produced by austenitizing and cooling in air. A widely used industrial definition describes heating approximately 100°F above the upper critical temperature (Ac3 or Acm) followed by air cooling. That distinction matters because it separates normalizing from slower cooling anneals and from subcritical stress relief. In blades, normalizing is used after forging to improve uniformity, hardening response, and grain structure.

1.2 Annealing and subcritical treatments

Annealing is a broad category. For blades, two concepts are often conflated: full annealing (above critical, slow cooling) and subcritical annealing or stress relief (below critical). A key practical distinction is purpose: annealing aims at softening for cold work, while normalizing aims at homogenizing or refining internal structure. Subcritical cycles do not fully austenitize and therefore cannot perform the same carbide redistribution as a full normalize.

1.3 Thermal cycling

Thermal cycling is a non specific term that simply means heating and cooling steel. In knife work it commonly means the set of cycles performed after forging but before the final heat treatment, meaning before the final austenitize and quench. For technical clarity, define your cycles by peak temperature relative to critical temperatures, time at temperature, and cooling condition.

You might also like: Technical forging heat-treat handbook

2. Why normalization is used after forging

Forging can leave a blade with non uniform grain size from local overheating, high dislocation density from deformation, non uniform carbide distribution from partial dissolution or banding, and residual stresses from uneven cooling and hammering. Normalizing is widely used as a conditioning step to produce a more homogeneous microstructure, reduce banding, refine grain, and provide a more consistent response when hardening.

3. What normalizing actually changes

3.1 Austenitization sets the reset point

When you heat above the transformation range, ferrite and pearlite transform to austenite. The prior microstructure is not erased instantly. Carbon and alloying elements must diffuse for carbides to dissolve and for composition gradients to even out. If you do not fully austenitize, you do not get a complete reset, and the steel can respond inconsistently to the final quench later.

3.2 Grain refinement is not guaranteed

Normalization can refine grain, but it can also coarsen it depending on peak temperature and time. Published work on steels shows that higher normalizing temperatures can increase final prior austenite grain size and reduce toughness. This is the core tradeoff in post forging cycles: enough temperature to transform and homogenize, but not so much exposure that grain growth dominates.

Figure 1 summarizes the refinement versus coarsening balance as thermal exposure increases.

3.3 Carbides and banding: what can move and what cannot

In simple carbon steels, cementite can dissolve relatively readily when you are fully austenitic, and carbon can redistribute over short distances. In alloy steels with strong carbide formers (chromium, vanadium, molybdenum), many carbides are more stable and dissolve more slowly. A major bladesmithing pitfall is chasing fine grain using only subcritical cycles: you may refine grain but leave carbide distribution largely unchanged.

3.4 Residual stress: what you remove and what you create

Reheating through transformation and controlled cooling can reduce prior forging stress. However, any cooling step can also introduce new stresses if the part cools unevenly. For blades, the edge and tip cool faster than the tang or spine, and that differential can reintroduce stress even if the forging stress was reduced.

4. Cooling is not one thing: why ‘air cool’ can mean different microstructures

Cooling in air spans a wide range of rates. Depending on steel hardenability and blade thickness, an ‘air cool’ after austenitizing can produce ferrite plus pearlite, bainite, or even martensite. That matters because harder transformation products increase residual stress and can make straightness harder to maintain before final heat treatment.

Figure 1 shows a typical post forging pattern: several normalize style cycles and then an optional subcritical stress relief step.

5. When normalization and cycling fix problems

The word ‘fix’ implies guarantees. A better goal is to increase the probability that the final heat treatment starts from a uniform condition. These are the cases where normalization and cycling usually help, and why.

- Non uniform grain from forging: Controlled reaustenitization can replace coarse grains with finer grains if peak temperature and time are managed.

- Inconsistent hardening response: Conditioning cycles that fully transform and improve homogeneity increase repeatability in final hardening.

- Residual stress from uneven forging and cooling: Transformation plus controlled cooling can reduce prior stress; subcritical stress relief can further reduce warping risk.

- Banding and carbide networks in simple alloys: Full austenitization can reduce visible banding and improve wear consistency; effects are limited in high alloy steels.

- Dimensional stability for later steps: Conditioning treatments can reduce surprise movement in later austenitize, quench, and temper steps by starting from a consistent condition.

6. When it does not fix problems

- Decarb at the edge: If the surface lost carbon, no cycle will put carbon back. You must remove decarb or prevent it.

- Cracks, tears, and hot short damage: Thermal cycling does not heal cracks. It can sometimes make them show up later.

- Severe overheating damage sometimes called ‘burning’: If grain boundaries were damaged or oxidized, normalizing cannot restore them.

- Severe segregation or inclusions from poor quality steel: Normalizing is not a true homogenization treatment.

- Carbide problems in high alloy or stainless steels: Stable alloy carbides may not dissolve in typical post forging cycles and can coarsen if held too long.

7. Detection: how to tell if you have a conditioning problem

7.1 Fracture appearance is a weak indicator

Coarse grain can produce a more faceted fracture appearance, but fracture appearance also depends on hardness and stress state. Use fracture as a clue, not as proof.

7.2 Metallography: the direct method

If you can etch and view the microstructure, you can directly evaluate pearlite scale, carbide networks, and banding that correlate with cooling rate and conditioning effectiveness.

7.3 Hardness mapping and coupons

Run small coupons of the same steel through your conditioning and final heat treatment and compare hardness and bend or impact proxies. If results vary widely, the issue is often inconsistent austenitization or inconsistent starting microstructure.

8. Cycle design principles for blades

8.1 Choose peak temperatures by critical temperatures, not by color

Color is not a temperature measurement. Critical temperatures shift with composition. If repeatability matters, measure temperature or use a controlled furnace rather than relying on surface color.

8.2 Control time at peak temperature

Time matters because grain growth is time and temperature dependent. In blades the goal is usually uniform temperature through the section, not long soaking. Long soaking increases oxidation and decarb risk.

8.3 Cooling practice is part of the process

If your goal is a consistent conditioning result, you need a consistent cooling condition. Spacing, airflow, and stacking change cooling rate and therefore microstructure.

8.4 Limit the number of full austenitizing cycles

Each full austenitizing cycle increases oxidation and decarb risk. Use enough cycles to reach a uniform starting condition, then stop.

9. Alloy family notes

9.1 Simple carbon steels

In simple steels, full austenitization cycles can meaningfully reset the microstructure. They are forgiving compared with high alloy steels, but overheating and long soaks still drive grain growth and toughness loss.

9.2 Hypereutectoid steels

Steels above eutectoid carbon contain excess carbides. Partial carbide dissolution is often the deciding factor for hardness potential and toughness. Too little dissolution can cause low hardness; too much temperature exposure accelerates grain growth.

9.3 Alloy steels and stainless

As alloying increases, stable carbides become more important. Cycles that work well for simple carbon steels can be ineffective or counterproductive in stainless or high alloy tool steels. Manufacturer heat treat data and controlled furnaces matter more than forge color heuristics.

10. Practical mapping: choose the right conditioning target

| Your problem | Most likely cause | What a normalize or cycle can do | What it cannot do |

| Chipping at moderate hardness | Coarse grain or brittle products from overheating or inconsistent cooling | Improve starting condition if cycles are controlled | Fix decarb, remove inclusions, heal cracks |

| Hardness varies along blade | Non uniform austenitization or cooling differences | Increase uniformity before final quench | Override poor final austenitize or quench practice |

| Warping during quench | Residual stress plus non uniform transformation | Reduce forging stress; make starting condition more uniform | Guarantee straightness in an aggressive quench |

| Poor edge stability | Carbide distribution issues or insufficient austenitization | Improve hardening response; reduce banding in simple steels | Transform stable carbides in high alloy steels without proper controls |

FAQ

- If I normalize three times, is grain always fine?

No. Grain size is controlled by peak temperature and time. Multiple cycles can refine grain if correctly targeted, but higher temperatures or long soaking can grow grain and reduce toughness.

- Does subcritical cycling replace normalizing?

Not if you need carbide redistribution and a full reset. Subcritical cycles are better thought of as stress relief or machinability oriented steps.

- Why do two makers get different results with ‘the same normalize’?

Because ‘air cool’ spans a wide range. Stacking, airflow, and section thickness change cooling rate and therefore the resulting microstructure and stress state.

About the author

Yashar Mousavand is a bushcraft and survival instructor and the founder of Yashar Survival Academy. He teaches practical field skills and writes evidence based guides on knives, gear, and outdoor technique, focused on what reliably works in real conditions.

References and further reading

Sources selected for stable definitions and technical background on normalizing, cooling rate effects, and grain size changes.

R1: Herring, D.H., Normalizing (Heat Treat Doctor PDF). Defines normalizing and lists reasons including stress reduction, homogeneity, response to heat treatment; describes heating about 100°F above Ac3 or Acm then air cooling.

https://heat-treat-doctor.com/documents/Normalizing.pdf

R2: Heat Treat Today, Why Normalize, and Is a Still Air Cool Really Important? Part 1. Discusses why normalize and how ‘air cooling’ spans many cooling conditions and microstructures.

https://www.heattreattoday.com/why-normalize-and-is-a-still-air-cool-really-important-part-1/

R3: American Bladesmith Society, Some Very Basic Confusion On Normalizing And Annealing (Kevin Cashen response). Distinguishes normalizing vs annealing by purpose; discusses carbide redistribution and temperature practices in bladesmithing.

https://www.americanbladesmith.org/community/heat-treating-101/some-very-basic-confusion-on-normalizing-and-annealing/

R4: Metals (MDPI), Heat Treatment and Austenitization Temperature Effect on Microstructure and Impact Toughness of an Ultra-High Strength Steel. Reports higher normalizing temperature increased prior austenite grain size and slightly reduced toughness in that study.

https://www.mdpi.com/2075-4701/11/5/723

R5: Mo et al., Effect of the Normalizing Temperature on the Size and Homogeneity of Austenite Grain in 20CrMnTi gear steel (Springer). Abstract discusses how normalizing temperature impacts austenite grain size and uniformity and how excessive downstream exposure can lead to coarsening and mixed grain.

https://link.springer.com/article/10.1007/s13369-024-09485-6

R6: Knife Steel Nerds, How to Thermal Cycle Knife Steel. Discusses thermal cycling as post forging steps before final austenitize and quench.

https://knifesteelnerds.com/2021/08/28/how-to-thermal-cycle-knife-steel/